After assessing and documenting damage from collisions or weather, skilled technicians clean and prepare vehicles using specialized tools to remove dents and straighten panels. Parts replacement focuses on genuine or approved components, with careful disassembly, reuse where possible, and precise reassembly following manufacturer guidelines. A final quality assurance check ensures panel alignment, functionality of systems, and overall cosmetic and structural integrity through advanced tools and techniques.

“Uncover the meticulous steps involved in an optimal auto body repair process, adhering strictly to manufacturer guidelines. From initial damage assessment and vehicle preparation to parts replacement and final quality checks, each phase is crucial for ensuring both structural integrity and aesthetic perfection. Discover how this systematic approach, encompassing precision assembly and rigorous inspections, delivers top-tier repairs that restore your vehicle to its original condition.”

- Assessing Damage and Preparing the Vehicle

- Parts Replacement and Assembly Procedures

- Final Inspection and Quality Assurance Checks

Assessing Damage and Preparing the Vehicle

After a collision or weather event like heavy storms or hail, the first step in any auto body repair process is a thorough assessment of the vehicle’s damage. This involves a meticulous inspection to identify and document every impacted area. Skilled technicians examine the exterior for dents, scratches, cracked components, and any structural damage. They also inspect the interior, checking for airbag deployment, fluid leaks, and potential safety system malfunctions.

Preparing the vehicle for repairs is crucial. This includes cleaning the affected areas, removing debris, and ensuring proper ventilation. In the case of Mercedes-Benz collision repair or hail damage repair, technicians might use specialized tools to pop out dents, straighten panels, and restore the vehicle’s original shape. The goal is to create a clean canvas, ready for precise repairs that match the manufacturer’s guidelines, ultimately leading to an outstanding vehicle restoration.

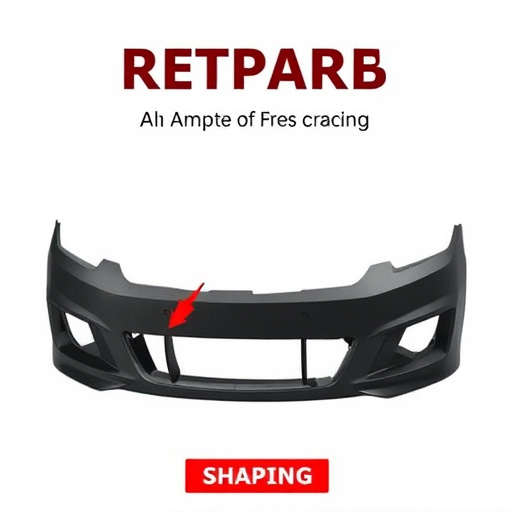

Parts Replacement and Assembly Procedures

In an auto body repair process that adheres to manufacturer guidelines, parts replacement and assembly procedures are critical steps. The first phase involves thoroughly inspecting the damaged areas to identify components requiring replacement. This meticulous process ensures that only genuine or approved-by-manufacturer parts are used, maintaining the vehicle’s original integrity and safety standards. Each part is carefully disassembled from the car, with special attention given to retaining and reusing functional pieces whenever possible.

The assembly phase requires skilled technicians who follow precise protocols. They begin by preparing the necessary surfaces, ensuring they are clean, dry, and free from debris. Then, new or repaired parts are fitted, aligned, and fastened according to the manufacturer’s specifications. This involves using the correct tools, fasteners, and techniques to guarantee a secure connection that meets the vehicle’s structural requirements. Once assembled, each component is thoroughly tested for functionality and fit before moving on to the next step in the auto body repair process.

Final Inspection and Quality Assurance Checks

After the auto body repair process is complete, the final step involves a thorough inspection and quality assurance check. Skilled technicians meticulously examine every aspect of the repaired car bodywork, ensuring that all components are aligned correctly and meet the manufacturer’s standards. This includes verifying the proper fit and finish of panels, checking for any visible imperfections or misalignments, and testing various systems to guarantee their functionality.

During this critical phase, advanced tools and techniques may be employed to assess the overall quality of the vehicle restoration. These checks ensure that the autobody repairs are up to par, addressing not just cosmetic concerns but also structural integrity and safety standards. By adhering to these rigorous procedures, auto body shops maintain high-quality craftsmanship, ensuring customer satisfaction with the final results.

When conducting an auto body repair process that follows manufacturer guidelines, it’s crucial to maintain precision and adhere to each step meticulously. From assessing damage and preparing the vehicle, to parts replacement, assembly, and final inspection, every phase plays a vital role in ensuring the restoration of the car to its pre-incident condition. By combining expert skills with standardized procedures, auto body repair professionals can deliver high-quality work that satisfies both manufacturers’ standards and customer expectations. This meticulous approach not only guarantees structural integrity but also preserves the vehicle’s overall aesthetic appeal, ultimately fostering a seamless driving experience.