In auto body repair, accuracy is key to achieving high-quality results. From frame straightening using advanced equipment to precise measuring techniques and Computer-Aided Design (CAD) software, every step ensures structural soundness and visual appeal match the original vehicle. Reputable workshops prioritize consistency and minimize errors through standardized operating procedures, advanced training, and the latest technologies, ultimately delivering auto body repair process satisfaction for customers.

In the precise world of auto body repair, accuracy is paramount. A single misplaced bead of paint or an imperfect weld can compromise the structural integrity and aesthetic appeal of a vehicle. This article delves into the profound impact of accuracy in the auto body repair process, exploring key aspects that contribute to seamless repairs and strategies for maintaining consistency and precision from start to finish. Understanding these elements is crucial for ensuring both safety and customer satisfaction.

- Understanding the Impact of Accuracy in Auto Body Repair

- Key Aspects That Contribute to Accurate Auto Body Repairs

- Strategies for Ensuring Consistency and Precision Throughout the Process

Understanding the Impact of Accuracy in Auto Body Repair

In the meticulous world of auto body repair, accuracy is paramount. Every precise cut, measurement, and application during the repair process directly influences the car’s structural integrity and aesthetic appeal. A slight misstep can lead to misaligned panels, uneven surfaces, or inadequate strength, compromising both the vehicle’s safety and resale value.

Consider a scenario where a fender needs replacement due to a collision. Skilled technicians utilize advanced tools and techniques to ensure every curve and contour of the new fender matches the original seamlessly. This meticulous attention to detail, from selecting the right materials to mastering specific painting techniques like auto detailing and auto painting, is what transforms a damaged vehicle into a near-perfect one. Understanding the impact of accuracy in these areas is key to delivering top-quality repairs that satisfy customers and uphold the integrity of the entire auto body repair process.

Key Aspects That Contribute to Accurate Auto Body Repairs

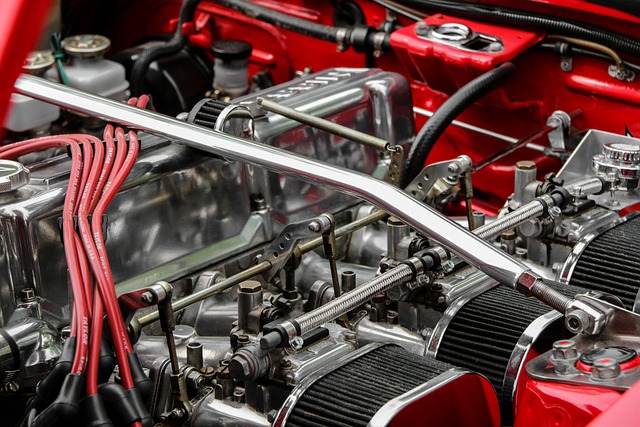

The success of auto body repairs hinges on meticulous attention to detail at every stage of the process. Several key aspects contribute to ensuring accurate and effective auto body repair. Firstly, proper frame straightening is foundational; it involves aligning the vehicle’s framework to its original specifications, which is crucial for structural integrity and safety. Technicians use advanced equipment to measure and adjust the frame, minimizing discrepancies that could compromise the vehicle’s performance and handling.

Secondly, skilled technicians employ precise measuring techniques and specialized tools throughout the repair process. This includes using laser scanners or traditional measuring tapes to capture exact dimensions of damaged areas, ensuring replacement parts fit seamlessly. Additionally, computer-aided design (CAD) software facilitates accurate detailing, allowing repairs to match the vehicle’s original specifications down to the smallest measurement. Incorporating these methods into the auto body repair process yields high-quality outcomes and ensures customer satisfaction in restored vehicles.

Strategies for Ensuring Consistency and Precision Throughout the Process

Maintaining consistency and precision throughout the auto body repair process is paramount to delivering high-quality results. To achieve this, reputable workshops employ several strategies. Firstly, standardized operating procedures (SOPs) are established for each step of the repair, from initial assessment to final inspection. These detailed guides ensure that every technician follows the same meticulous approach, minimizing errors and variations. Secondly, advanced training and continuous education keep the team updated with the latest techniques and technologies in automotive repair, enhancing their skills and precision.

Additionally, utilizing specialized tools designed for bumper repair and car paint services plays a pivotal role. These tools are calibrated regularly to guarantee accuracy during intricate tasks such as panel alignment and paint application. Moreover, implementing digital measurement systems and computer-aided design (CAD) software allows for precise measurements and detailed planning, ensuring that every repair is tailored to the specific vehicle’s needs.

Accuracy in the auto body repair process is paramount for ensuring vehicle safety, customer satisfaction, and long-lasting repairs. By focusing on key aspects such as precise measurements, high-quality materials, and consistent techniques, auto body shops can deliver top-notch results. Implementing strategies for consistency and precision further solidifies the quality of work, making accurate auto body repair a cornerstone of the industry’s success in meeting modern driving standards.